The Client

Our Customer is the largest shopping centre in Far North Queensland and has been servicing the local region since 1997.

Requirement

Our client required the Cairns Central to do high cleaning with many Custom requirements. The requirements included using the newly added Ionic Wash systems to clean external glass surfaces in a safe and efficient manner.

Outcome

Hudor was able to complete the works to a high standard which was far beyond the expectations of the client.

Introduction

In 2016, Hudor was contacted to provide a quotation for the high clean at Cairns Central following a dispute with the current contractor who was carrying out the works. As the cleaning contract included the high clean works, the cleaning company, who had been using Hudor for their periodical works in Brisbane over the years, decided to engage Hudor for the works at Cairns Central.

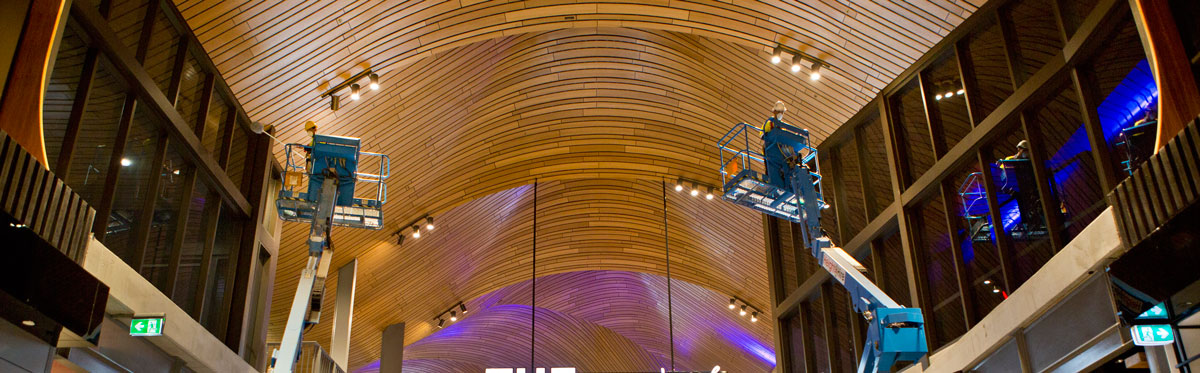

With constant and detailed communication between the project manager and the Centre Management throughout the project and the expert use of mobile elevated work platforms and newer cleaning systems, Hudor was able to complete the works to a high standard which was far beyond the expectations of the client.

The Challenge

The contractor that was used by the centre prior to Hudor’s initiation had failed to deliver the required services in the scope of work over the years.

Our client approached Hudor Cleaning Services with the following brief. The website needs to:

- The centre had a number of issues from birds nesting on the roof supports to years of built up grime on all fixtures above 5 metres.

- The centre also had weight restrictions on certain slabs which had to be accounted for when using MEWPs.

- The previous works had all been carried out using scissor lifts due to these restrictions and the lack of knowledge from local contractors regarding the safe and efficient use of MEWPs.

The Solution

After the initial walkthrough, Hudor was quick to start contacting EWP suppliers to identify the ideal plant for the scope of work from what was available in the region.

We began by highlighting the key areas which needed to be addressed. Then Hudor came into these solutions:

- Hudor’s project manager decided on using a few MEWPs for the project each with different reach and range of motion to ensure safety and efficiency.

- Following the initial project costing, changes to the scope were made to tailor the scope of work to the requirements of the client at that point in time.

- The tasks also included using the newly added Ionic Wash systems to clean external glass surfaces in a safe and efficient manner.

- The safe work method statements had been carefully generated with attention to the different load rating of the centre and maps were attached with no-go zones for each MEWP.

- With the better MEWPs and more efficient cleaning systems, Hudor’s team flew up towards the tropical climate of the North ready to tackle the largest and the most technical project undertaken by the company so far.

The HUDOR Difference

Throughout the project, the client was sent daily reports including the progress of the works and any issues that the team had come across. The issues ranged from electrical safety to roof leaks which was much appreciated by the client. Daily walkthroughs were also conducted to clarify any concerns from both parties.

The safety of the team was utmost priority for Hudor as the weight limitations eventually caused concerns with accessing certain sections of the centre. This was overcome by the brilliant strategies used by the project manager to ensure the safety of the team while completing the requests from the client.